QM MAX

Line up

※左右にフリックしてご覧いただけます。

| Cat. No. | Type | Tool diameter (ΦDc) |

|---|---|---|

| QXP | Facemill type | Φ40~Φ66 |

| QXP | Shank type | Φ16~Φ40 |

| MQX | Modular head type | Φ16~Φ42 |

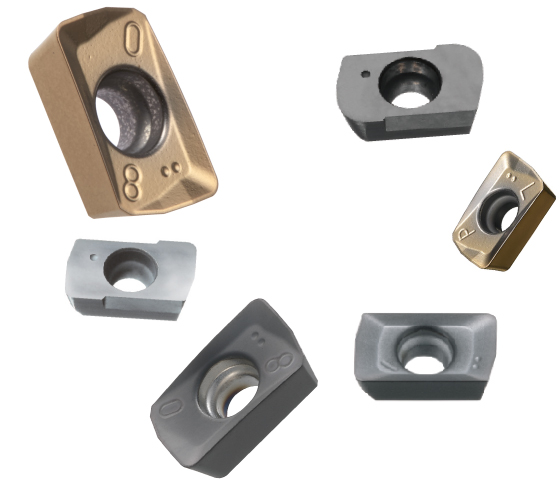

Features of Products

EP ** type insert achieves metal removal rate : 144cc/min

Possible to machine low depth of cut and ultra

high-feed machining with Max.ap=1mm.

Achieved metal removal rate 144cc/min by

dia. 32 mm tool. Applicable from general steel to high-hardened steel of 60 HRC.

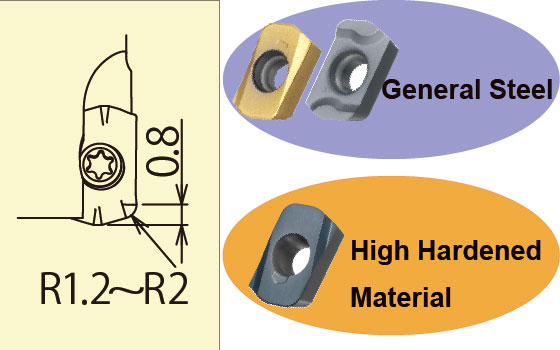

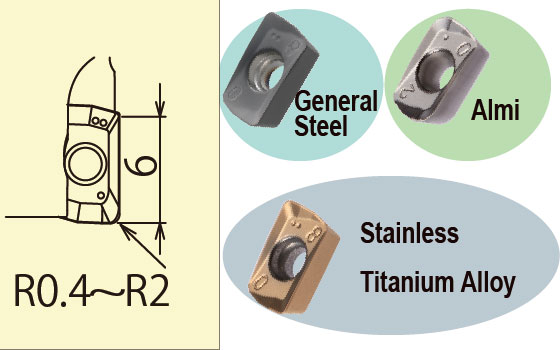

ZPMT type inserts achieves

shoulder milling of

Max.ap=1.0mm

Shoulder insert for roughing to semi-finishing of

side or bottom surface. Max.ap is 6.0mm. There are 3 types of corner radius sizes ; R0.4,R0.8, and R2.0.They are applicable for the machining of

corner R parts.

YPHW insert realizes

high-efficient and high-precision machining.

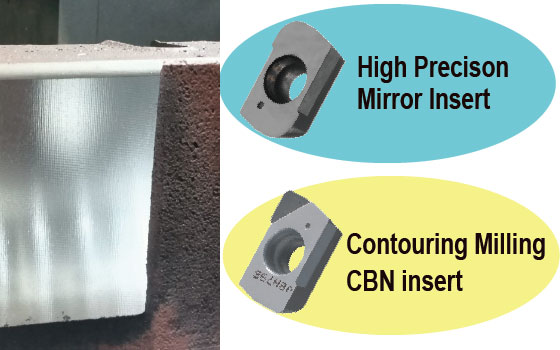

Mirror insert is the insert for side and bottom

surface finishing or for contouring milling.

It realizes better finishing surface.

In case the application of better finishing surface

is required, you can use CBN insert.

FAQ about QM Max

Q

Is there any insert for up and down cutting ?

A

Following inserts can use for up and down cutting.

YPHW1003**ZER-15、YPHW100308ZER-F1、YPHW100308ZER-F