- HOME

- DIJET INDUSTRIAL CO., LTD

- Solutions by industry

Solutions by industry

Automotive Industry

The automotive industry is one of the key

industries in the world.

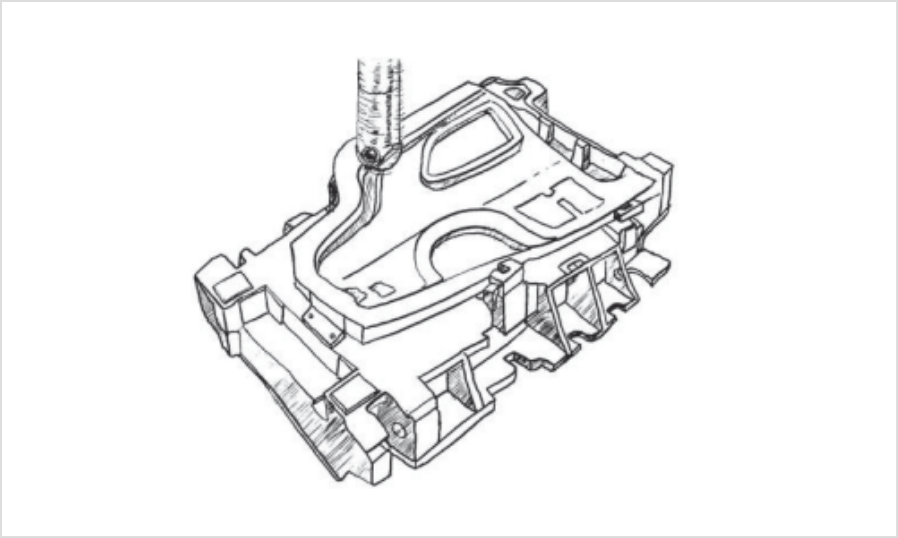

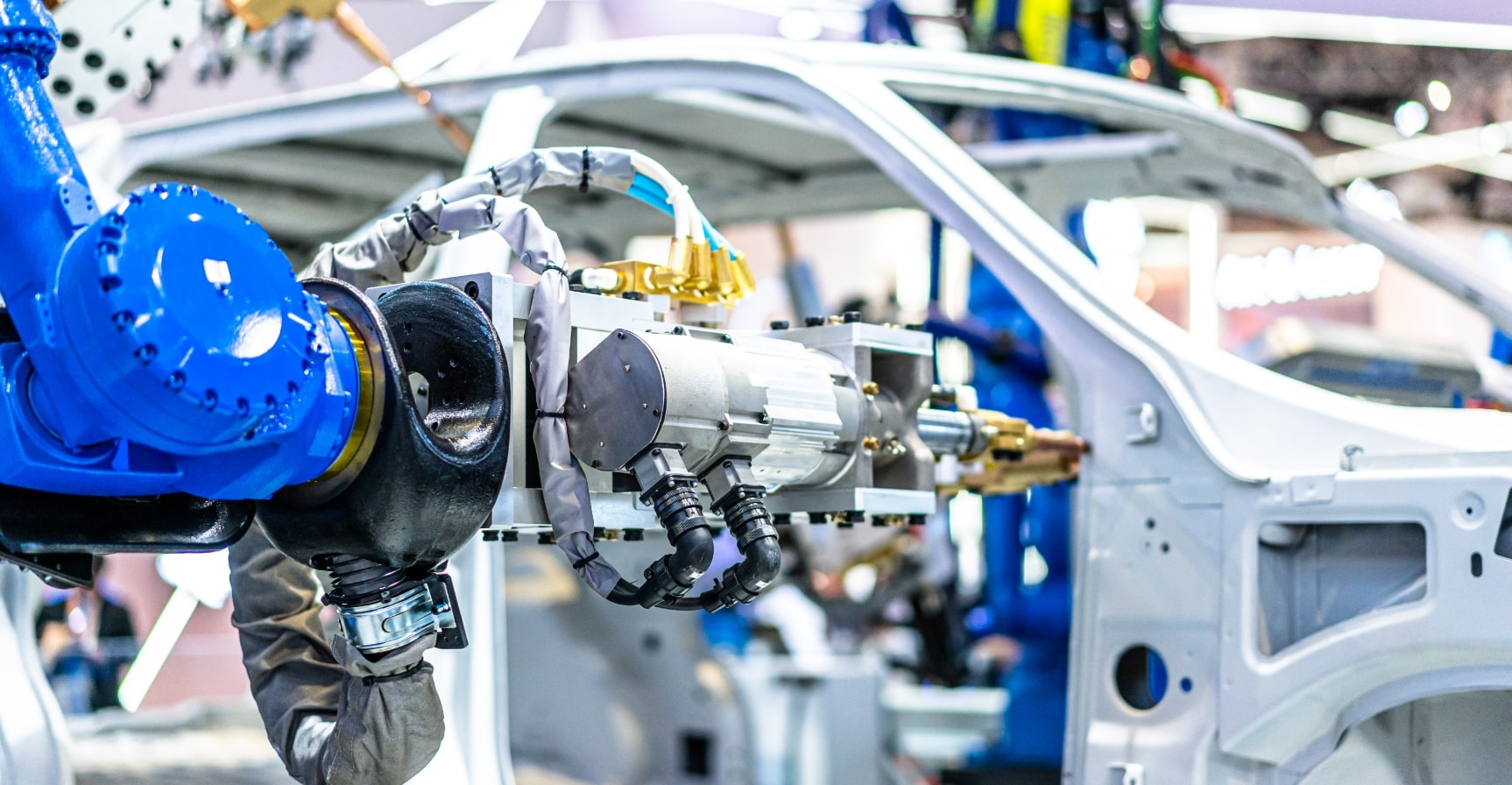

In automotive manufacturing, there are many

manufacturing processes, and the efficiency of

the machining process of automotive parts has a great impact on the efficiency of operations.

In the automotive industry, our products

contribute to improved productivity, process

reduction, and cost reduction at the

manufacturing facilities.

Products used in the automotive industry

Drills

Our drills make a straight hole in materials such

as general steel and carbon steel, cast iron, and

stainless steel.

EXSKS

Economical double-side insert(6 corners).

Possible to high feed machining on fz=2mm/t

case of Max. depth of cut(ap)=3mm.

End mills for

aluminum machining

Long-selling product with a wide range of size

variations.

Long shank type” and “under-neck type” etc.,

which can attentive products, improve

productivity in aluminum alloy machining.

Aerospace Industry

As aircraft fly through the skies around the world, the needs for lighter and stronger airframes and

aerospace parts are increasing every year.

Our products are used in the machining of aircraft airframes and various parts that are susceptible

to such weather and temperature changes.

Products used in the aerospace industry

EXSAP

Shoulder cutter with 4 corners on double sides

high efficiency, and multi-functional use.

17 type enables highly efficient roughing to

medium finishing with a high depth of cut

Max.ap=15mm. 11 type is a multi-blade

specification for highly efficient high-speed

machining. DS1 coated inserts for machining

heat-resistant alloys are added.

SKS G-Ⅱ 09 type

High-efficiency, high-feed cutter with emphasis on sharpness, specialized for machining

difficult-to-cut materials. Multi-flute specification of small inserts with 4 corners on one side.

Straight cutting-edge diameter and strong axial

design reduce cutting resistance and enable

stable machining of difficult-to-cut materials.

Indexable EZ Drill

In addition to general-purpose inserts capable of machining stainless steel, general steel to carbon steel, cast iron, etc., inserts for

machining difficult-to-machine materials such as heat-resistant alloys are also added to the lineup.

Major Case Studies in the Aerospace Industry

One-cut Silent Radius suppresses vibration even in

thin-walled workpieces and provides a perfect finish!

| Company | Aircraft manufacturer |

|---|---|

| Tool | DV-OCSAR type |

| Machining Applications |

Blade machining |

| Improvement details |

Even with thin-walled workpieces prone to chattering, the one-cut Silent Radius suppressed chattering and enabled stable cutting. |

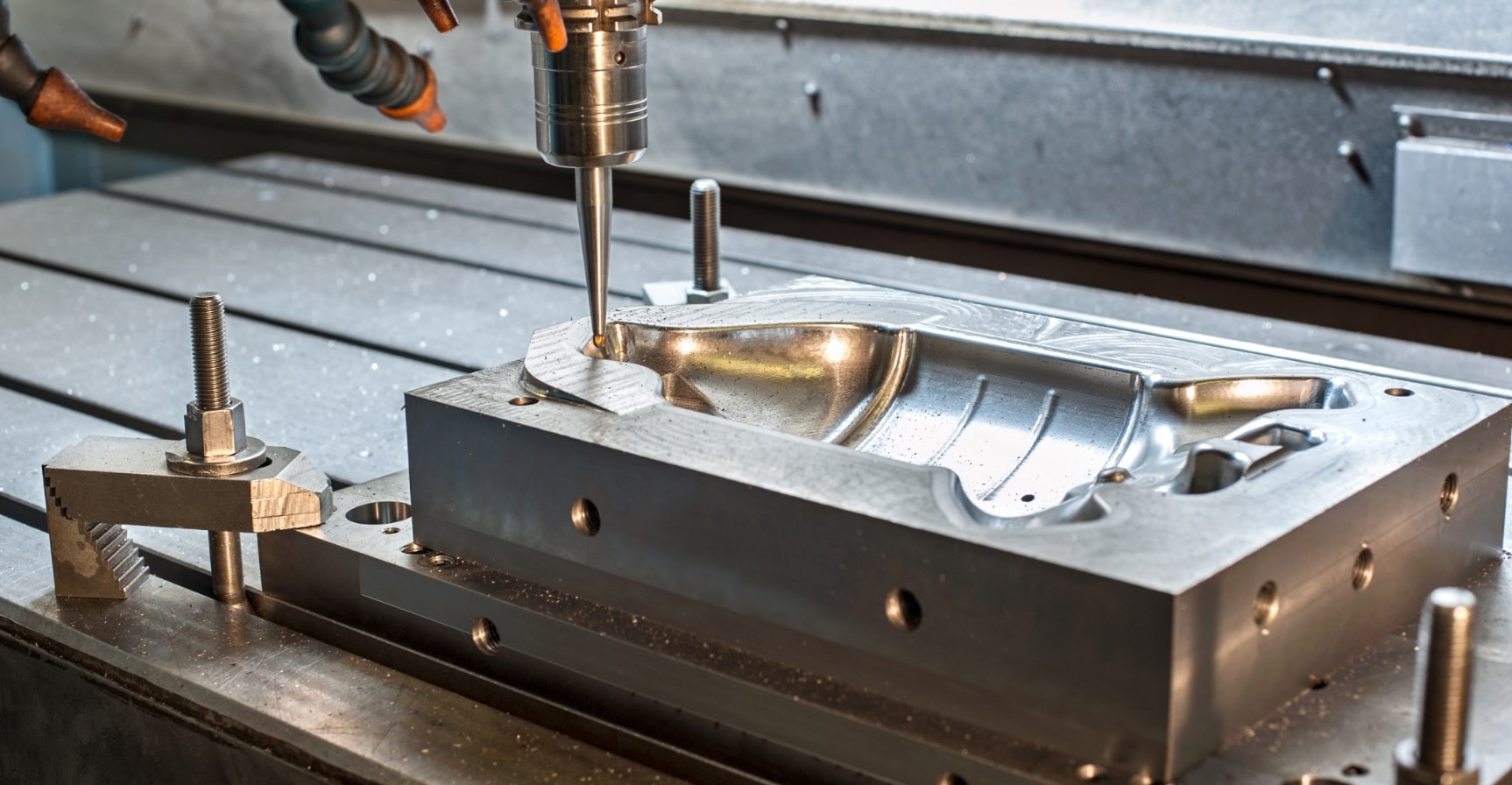

Die and Mold Industry

Dies are the molds used to make all kinds of

products, and high-performance machining tools are required because high-precision, high-quality dies affect the performance and appearance of

the parts for which they are made.

Our company contributes to die and mold

machining with carbide machining tools, which is our strength in die and mold machining.

Products used in the Die and Mold industry

EXSIX

Indexable shoulder milling cutter EXSIX has high

rigidity 6 corners insert.

Due to unique 3D insert shape, axial rake angle is positive, therefore EXSIX achieve low cutting

force and good chip evacuation. It is usable for

wide applications such as face milling, slotting

and plunging.

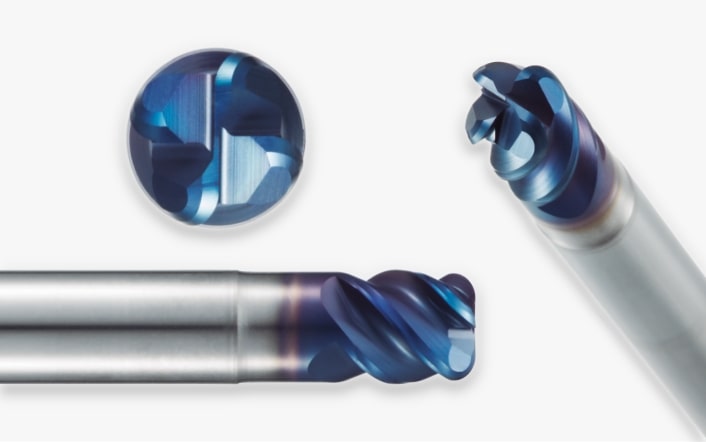

SFSR

4-flute solid radius end mill for a wide range of

roughing and finishing processes in hard

materials up to 70HRC. Tool rigidity is improved

by setting the blade length to 1D and unequal

division. Adoption of unequal pitch and irregular

helix flutes solved vibration problem. Good

surface finish can be obtained and chipping

during machining is suppressed.

MIRROR BALL

DIJET’s popular effective 2-flute interchangeable cutting-edge ball nose end mill.

Even the Indexable tool the machining accuracy is equivalent to solid ball nose end mills.

Tools for finishing a wide variety of work

materials by selecting the cutting-edge twist

shape and material grade.

Products used in the Die and Mold industry

Improved tool life in press die machining

| Company | Press die manufacturer |

|---|---|

| Tool | Mirror ball C-Body |

| Machining Applications |

Finishing |

| Improvement details |

The 60HRC high-hardened material finishing process achieves a long tool life of 9 hours, compared to 6 to 7 hours for conventional products. |