- HOME

- DIJET INDUSTRIAL CO., LTD

- Strength of DIJET

Strength of DIJET

3 strengths point of DIJET

Integrated Production

80 years of trust and

achievement

Leading company of tools

for Die and Mold machining

STRENGHT 01

INTEGRATED PRODUCTION

Cemented carbides are mainly composed of tungsten carbide and cobalt, but their properties vary greatly depending on the combination ratio, additives, and grain size.

The performance of cutting tools can be dramatically improved not only by optimizing the cutting-edge shape to suit the application and work material, but also by surface treatment.

DIJET offer integrated manufacturing services from granulation and preparation of raw materials to sintering of alloys, grinding and coating of tools.

This makes it possible to supply high-quality tools.

STRENGHT 02

80 years of trust and achievement

For more than 80 years since our establishment in 1938, we have been supplying tools to various industries as a specialized manufacturer of cemented carbide tools.

In 1997, all of our domestic offices acquired ISO9001 certification, and almost all of our new products are manufactured in Japan.

By supplying products of stable quality, we are able to offer our

customers the best solutions to their problems.

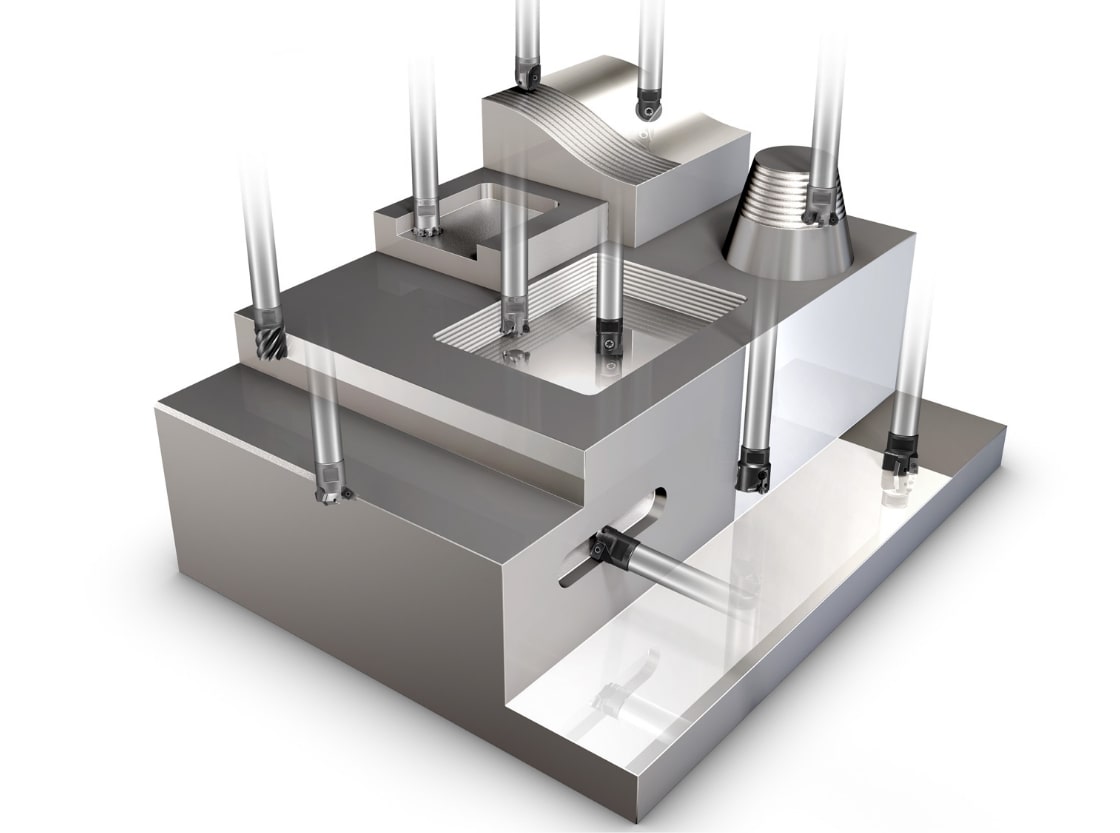

STRENGHT 03

Leading company of tools for Die and

Mold machining

We have especially focused on the development and commercialization of die and mold tools.

We have contributed to the development of the mold and die industry through our highly original products, such as the “Mirror Series” that realizes “surface beauty like mirror” in finishing processes, and the “5- AXIS Series” that dramatically reduces machining time by reproducing a large pick feed in 5-axis machining processes.