- HOME

- DIJET INDUSTRIAL CO., LTD

- Products

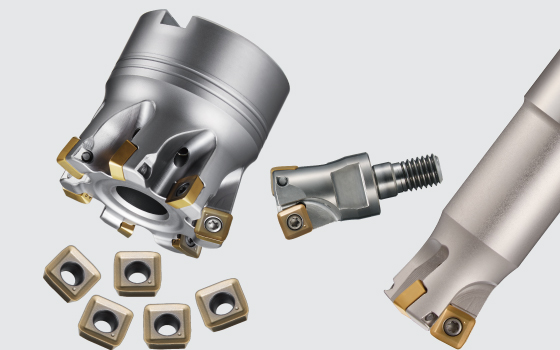

- Indexable tool for high feed machining

Indexable tool for high feed machining

SKS Series realizes higher efficiency by high machine power

with depth of cut of 3 mm or less.

The QM series, with a depth of cut of 1 mm or less,

realizes high speed high feed machining

to increase machining efficiency.

QM series, etc.,which realize high machining efficiency

through high-speed,high-feed machining

with a depth of cut of 1 mm or less.

We realize customer's productivity improvement through highly efficient machining.

Product lists of Indexable tool for high feed machining

SKS EXTREME 09 type

Double side insert (6 corners).

"PM Insert" Max.ap=3mm.

"PL Insert" achieves stable and long life in

digging process. Max.ap=2mm.

SKS EXTREME 07 type

Double side insert (6 corners).

Max ap=2mm.

Combines sharpness and strength.

Well-balanced high feed machining is possible.

SKS EXTREME 05 type

Double side insert (6 corners).

Max ap=1.5mm.

By adopting multi blade specification

with small diameter, high efficiency and high feed

machining is possible.

QM MAX

A wide range of work materials and a wide range of machining are possible with a single holder.

Highly efficient machining is realized with

multi-blade specification of 2 corners (10 sizes) .

QM MILL

Adopted unique 3D geometry inserts

with low cutting force and multi blades

specification,even if small inserts

QM MILL acieved high speed

and high effcient machining.

SKS-GⅡ

Lineup includes 10 and 14 types of square

positive inserts with 4 corners on one side

for highly efficient high depth of cut machining.

Suitable for digging in mold materials.

SKS-GⅡ 09type

Lineup includes 09 types of square positive

inserts with 4 corners on one side.

Highly efficient machining of hard-to-cut

materials such as heat-resistant alloys

and titanium alloys.