MIRROR BALL

Line-up

| Cat. No. | Type | Tool Diameter (ΦDc) |

|---|---|---|

| BNM-S/T/T-LS | BNM-S/BNM-T BNM-T-LS |

Φ16~Φ30 |

| BNM-S/T-C | BNM-S-C BNM-T-C |

Φ6~Φ30 |

| BNMU-C (Carbide shank) | BNMU-C | Φ16~Φ20 |

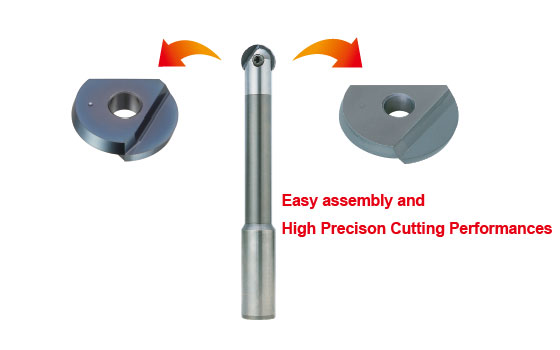

| MBX | Modular head type | Φ10~Φ30 |

Features of products

Ultimate precision indexable ball nose endmill

Insert R-accuracy is ±0.006mm or less, which

is as high as that of solid ball end mills.

2 to 3 times higher efficient machining can be possible

compared with conventional steel body,due to control

the vibration by the combination of Carbide shank

arbor.

Economical indexable

insert

MIRROR BALL finishing can replace with conventional

solid carbide ball nose end mill finishing. By adopting

economical indexable insert, tool costs of finishing

process can be reduced greatly without using solid

carbide ball nose end mills.

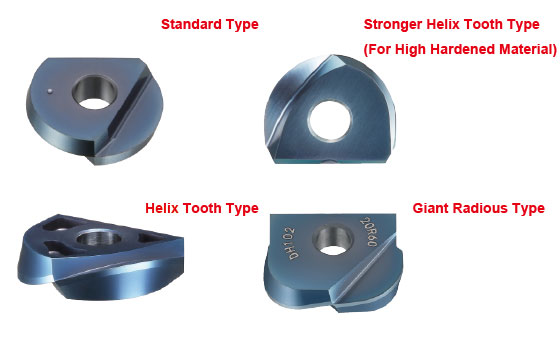

Suitable for a wide range of

work materials

Suitable for a wide range of work materials from general steel,prehardened steel,cast iron to difficult-to-cut materials such as stainless steel, titanium alloys, and heat-resistant alloys.

FAQ about Indexable tool for finishing

The grades JC4015, JC5015, and JC8003 seems to have been discontinued. Do you have any alternatives?

Yes. JC4015 and JC5015 switched to DH111, JC8003 switched to DH103.

Are undershank type holders available?

Yes. BNMU type is combined model with carbide shank. Modular head type

By combining MBX type and straight type carbide shank arbor, it becomes an under shank type holder.

I use a modular head attached to a carbide shank,

but it comes loose during use.

Please follow the instruction for the tightening torque specified in the catalog.

If the tightening torque is insufficient, the arbor may loosen due to cutting vibration.

On the other hand, if the tightening force is too much, the arbor may broken.