- HOME

- DIJET INDUSTRIAL CO., LTD

- Products

- End Mills

- One-Cut Silent Radius

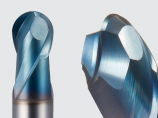

One-Cut Silent Radius

Line-Up

※左右にフリックしてご覧いただけます。

| Cat. No. | Corner Radius | Tool Diameter (ΦDc) |

|---|---|---|

| DV-OCSAR | 0.5~3.0 | Φ3~Φ20 |

Features of products

Perfect for heat-resistant alloys,

titanium alloys, and

stainless steel

by reducing vibration.

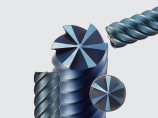

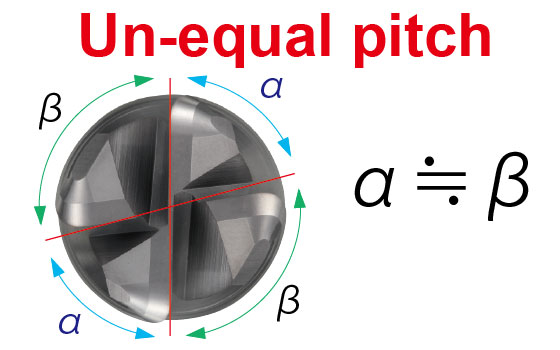

In addition to an unequal lead angle of 42°-45°,

unequal leads are also used

at the corner radius to achieve a one-rank

higher chatter suppression effect.

Perfect corner radius

in pocket milling

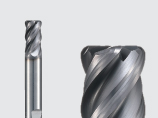

Good surface finish can be obtained

on thin-walled workpieces such as blades

and on corner radius in pocket milling

where machined surfaces tend to worsen.

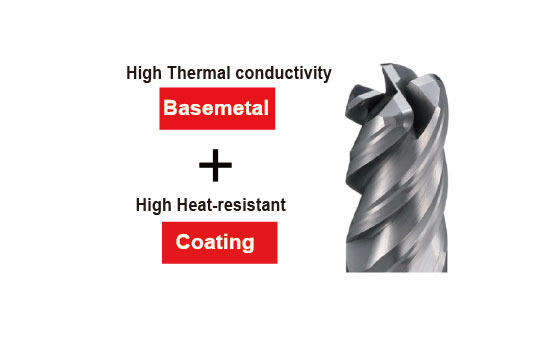

It achieved long tool life

with combination of

perfect base metal

and grade

Perfect for Inconel, heat-resistant alloys,

titanium alloys, etc.,

which are widely used in the aircraft industry.

FAQ about One-Cut Silent Radius

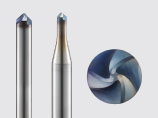

Q

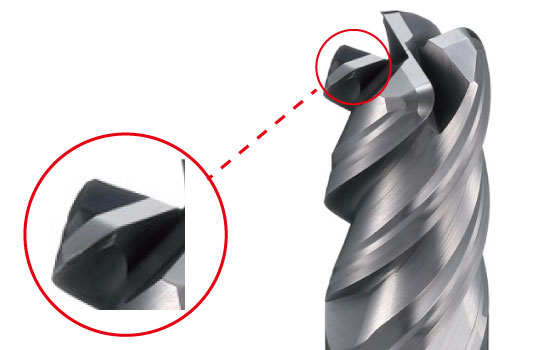

Is it possible to remove a convex protrusion on the top surface

of a titanium alloy and Inconel workpiece by Z-direction plunging?

A

Because the cutting edge extends to the center, it is possible to process

only to remove excess meat protruding from the convex shape.