One-Cut 70

Line up

※左右にフリックしてご覧いただけます。

| Cat. No. | Type | Tool diameter(ΦD) |

|---|---|---|

| SEHS/SEHH | Short/Regular | Φ1~Φ20 |

| SEHH-R02 | Regular with corner radius 0.2 | Φ3~Φ20 |

| SEHH-R | Regular with corner radius | Φ3~Φ20 |

| SEHM | Middle | Φ6~Φ20 |

| SEHL | Long | Φ6~Φ20 |

Features of products

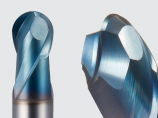

Achieved high-speed and

high-efficient machining of

high-hardened steel

by reducing deflection.

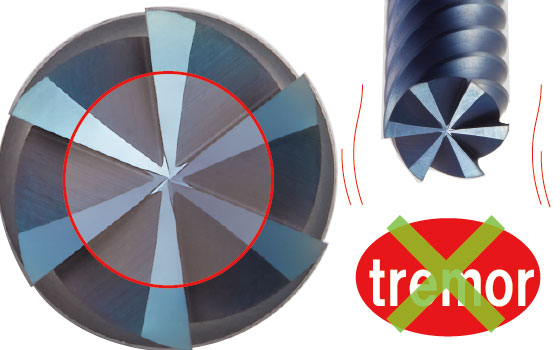

Designed with thicker core diameter reduces the deflection of tool minimamly. High-speed and

high-efficient machin-ing is possible until

high-hardened steel until 70 HRC.

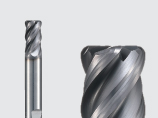

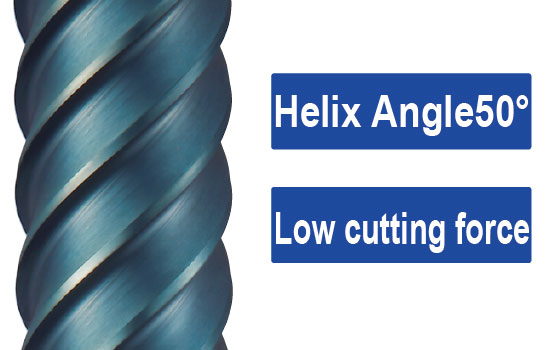

Thanks to low cutting force

geometry, high-precision machiningis possible from

semi-finishing to finishing.

The unique geometry keeps strength of cutting

edges and reduce cutting force. Applicable from

semi-finishing to finishing of high-precision

machining.

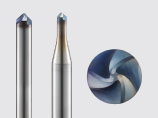

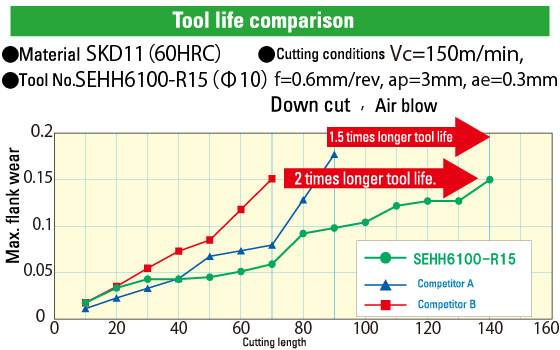

High-precision machining with

long tool life is possible even in

case the machining of

high-hardened steel.

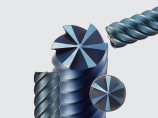

Cutting chips are evacuated smoothly from low

speed cutting to high speed cutting.

FAQ about one cut 70

Q

When using with same cutting parameter of old DV-SEHH type, the tool has broken.

Is there any solution ?

A

Please increase cutting speed from 10 to 20 % and reduce cutting force. SEHH type is adapted DH coat which is sperior in wear-resistance than

DV-coat, so it's possible.