- HOME

- DIJET INDUSTRIAL CO., LTD

- Products

- End Mills

- Chamfering cutter for high hardened materials

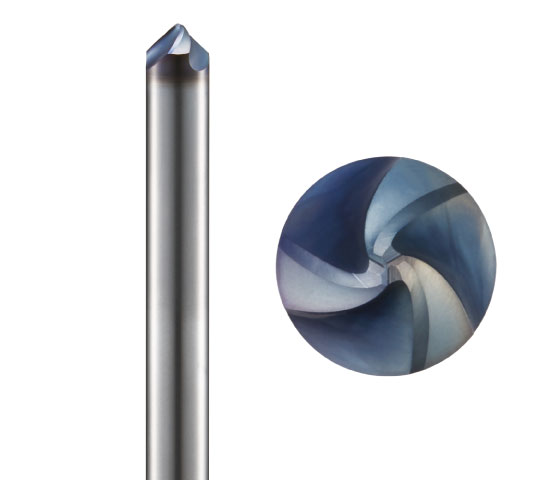

Chamfering cutter for high hardened materials

Line Up

※左右にフリックしてご覧いただけます。

| Cat. No. | Tool Diameter (ΦDc) |

|---|---|

|

SFSV |

Φ1~Φ12 |

Features of products

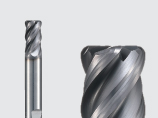

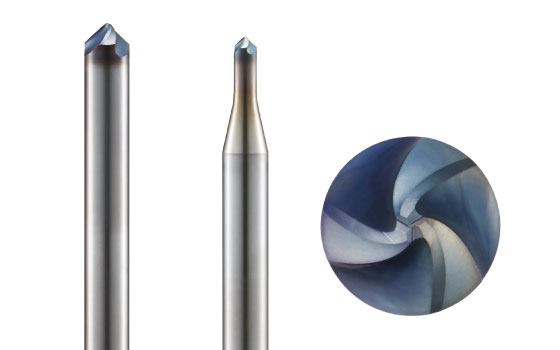

Solid chamfering cutter

capable of machining high

hardened materials (70HRC)

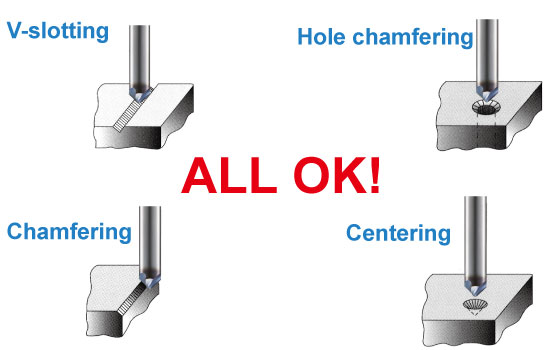

V-slotting, hole chamfering, chamfering,

and centering of high hardened materials

(70HRC)to general-purpose steel

are also available.

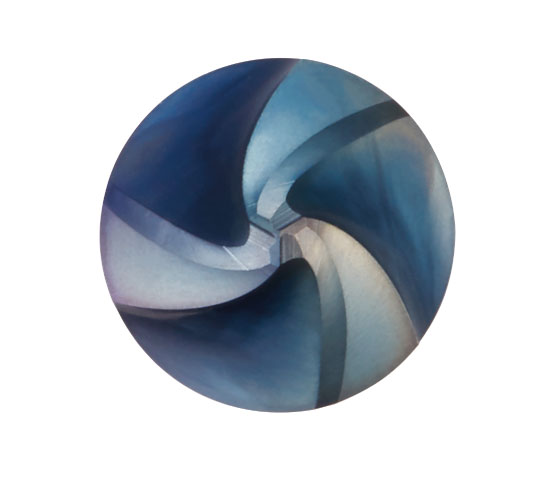

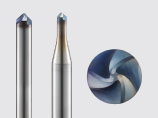

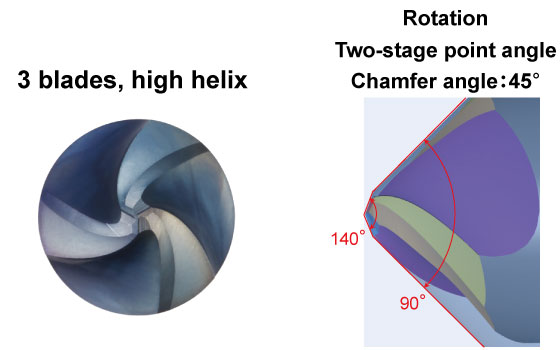

2-step tip angle

and 3-blade specifications

achieved high efficiency

and long tool life

The two-step tip angle with an obtuse angle

at the tip ensures rigidity of the cutting edge

and enables highly efficient machining.

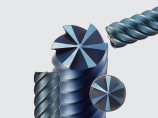

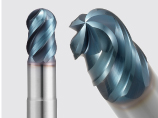

3-flute high helix shape enables

highly efficient machining of

not only hard materials

but also other work materials.

High-efficiency machining

of general-purpose materials

in the high-speed

rotational range is also possible

It has a shank accuracy (h5)

that can be adapted to shrink fit holders

and hydro tooling with rigidity

and precision at high speed rotation,

enabling highly efficient machining of

not only hard materials but also general-purpose

materials in the high-speed rotation range.

FAQ about Chamfering cutter for high hardened materials

Q

What is the tip angle of the chamfering cutter?

A

The tip angle is 90°.