- HOME

- DIJET INDUSTRIAL CO., LTD

- Products

- Drills

- Spot Facing Drill

Spot Facing Drill

Line-up

※左右にフリックしてご覧いただけます。

| Cat. No. | Drilling depth | Tool Diameter (ΦDc) |

|---|---|---|

| TLDM | 2D | Φ1~Φ14 |

| TLD3D | 3D(With coolant hole) | Φ3~Φ14 |

| TLD5D | 5D(With coolant hole) | Φ3~Φ14 |

Features of the product

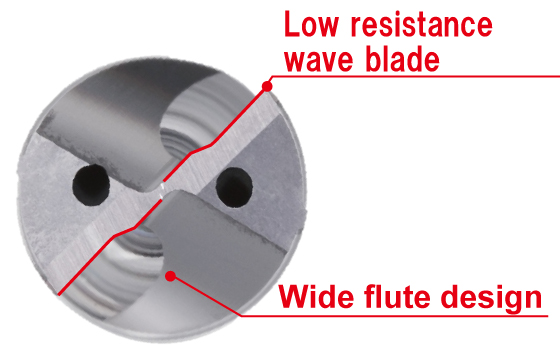

Low-resistance blade shape

and wide flute design

for long tool life

Wave cutting edges provide

low-resistance machining.

The wide flute design and

smooth surface treatment improves

chip evacuation and extends tool life.

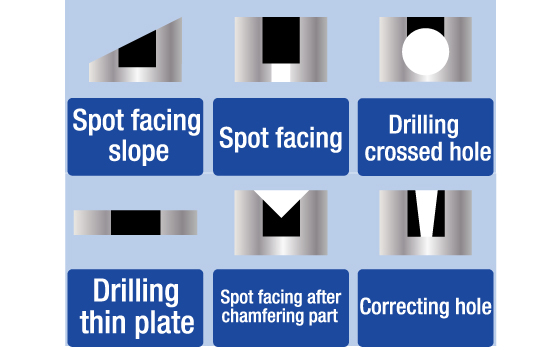

Because of multi application,

achieved process integration

It reduces machining time by consolidating

helical machining, etc.

with conventional end mills for multi-functional

applications such as drilling on inclined

surfaces and boring holes.

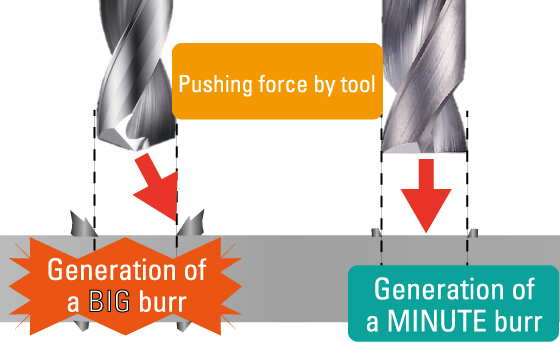

Restraing entrance burr

and exit burr

Useful in situations where burr processing

is difficult, such as crossed hole

processing

FAQ about carbide drill

Q

Is it possible to drilling without guide holes?

A

It is possible with TLDM type, TLD3D type.

When you use TLD5D type, a guide hole with a drilling depth about 0.5 to 1.0D is recommended.