- HOME

- DIJET INDUSTRIAL CO., LTD

- Products

- Drills

- EZ HARD DRILL

EZ HARD DRILL

Line-up

| Cat No. | Type and Drilling depth | Tool Diameter (ΦDc) |

|---|---|---|

| EZH | 5D | Φ2~Φ16.1 |

| EZH-02 | 0.02 over type・5D | Φ2.02~Φ16.02 |

| EZH-LS | Long shank type・5D | Φ3~Φ5 |

Feature of product

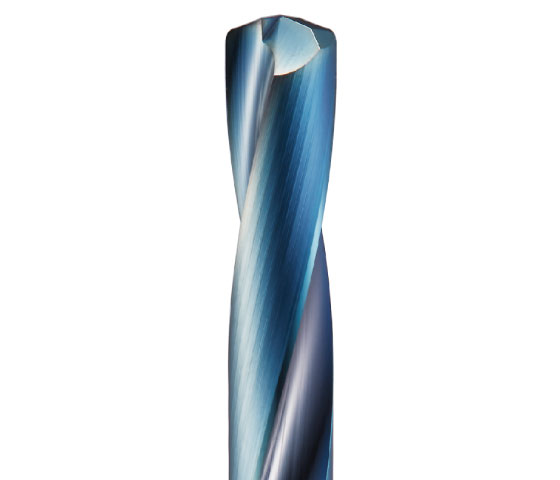

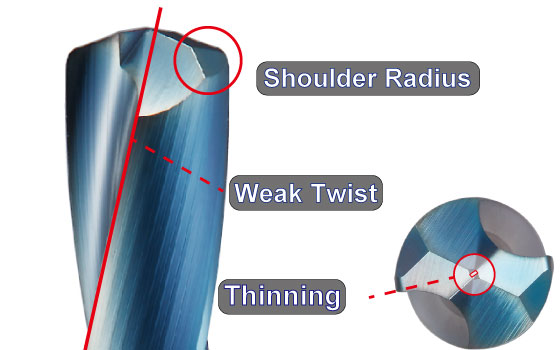

Gentle Helix angle degrees and

shoulder R for drilling of

high hardened materials up to 70HRC

Adopted helix angle 15 degrees

and shoulder radius prevent chipping.

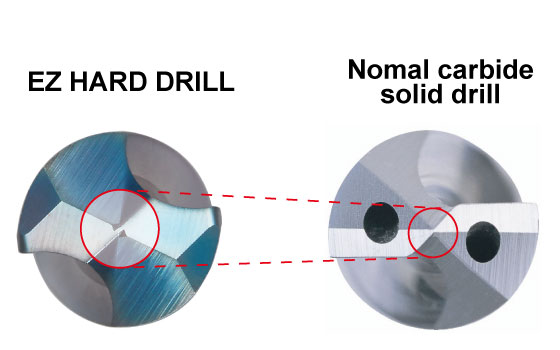

Thinning shape suitable for

high hardened materials

improved chip resistance at the center

of drill and chip evacuation.

Exclusive thinning for

high hardened materials

Web thickness is 1.6 times more

(compare with nomal carbide solid drill)

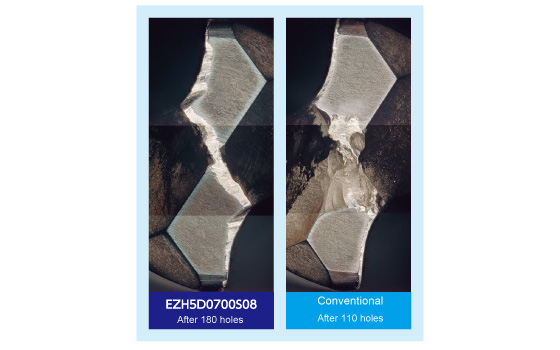

Stable drilling for high hardened materials

up to 70HRC by adopting “DH1” coating

By adopting “DH1” coating which provides high hardness

& oxidization resistance,

improved wear resistance and gives longer tool life.

Adopting micro grain carbide with high toughness,

improved chipping resistance.

FAQ about carbide drill

Is it possible to machining for carburization with EZ HARD DRILL?

Please Use EZ hard drills at first, and then STRIKE DRILL in the middle of machining.

※Please refer to the recommended cutting conditions for machining.

I am looking for a drill to remove a bolt breakage fracture.

We recommend EZ hard drill (EZH type).

A tool was broken when machining under catalog conditions. What are the countermeasures?

First, lower the feed speed. If it is not still working well, then lower the spindle speed as well.